Unveiling the Strength and Versatility of Spiral Woven Mesh

Introduction:

Spiral woven mesh stands as a remarkable material with countless applications, thanks to its exceptional strength and adaptability. This article explores the fascinating world of spiral woven mesh, shedding light on its features, diverse applications, and the multitude of benefits it brings to various industries.

The Composition and Construction of Spiral Woven Mesh:

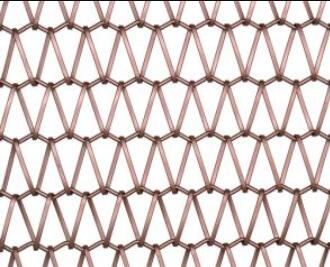

Spiral woven mesh is crafted through interlocking spirals of metal wire, forming a durable and flexible mesh structure. Typically made from stainless steel, this weaving technique grants the mesh resistance against corrosion, heat, and pressure. With options for customization, spiral woven mesh comes in different diameters, mesh sizes, and configurations to suit specific requirements.

Applications: A Multitude of Possibilities:

The versatility of spiral woven mesh finds expression in its broad range of applications. Often employed in filtration systems, it excels at separating solids from liquids or gases, offering precise filtration with high flow rates. Beyond filtration, spiral woven mesh finds utility in architectural projects, creating captivating visual effects and intricate patterns. Conveyor belts, machinery guards, insulation, and animal enclosures also benefit from the material's strength, flexibility, and durability. In industrial processes demanding reliable performance, spiral woven mesh emerges as a preferred choice due to its ability to withstand mechanical stress and harsh environments.

Additional resources:Are Galvanized Steel Garden Beds Safe for Plants? Exploring Pros & Cons

What are the advantages of wire mesh?

What is the introduction of steel structure building?

What are the advantages of ordering PPGI coils in Nigeria?

Spiral Heavy Weight Drill Pipe: Exploring Advantages

The Remarkable Power of 40x40x20mm Neodymium Magnets

Does copper mesh keep bugs out?

Advantages: Unleashing the Potential :

Spiral Architectural Mesh boasts several advantages that set it apart. Its interlocking spiral structure provides exceptional strength, enabling it to withstand rigorous mechanical stress. The material's impressive heat tolerance makes it suitable for applications involving high temperatures, such as industrial drying equipment and furnaces. Moreover, the corrosion resistance of spiral woven mesh ensures longevity and reliable performance even in corrosive environments. Its open structure facilitates efficient fluid flow, preventing clogging and enhancing filtration effectiveness. Furthermore, the ability to customize wire diameter, mesh size, and configurations empowers industries to tailor solutions to their specific needs, ensuring optimal performance and efficiency.

Conclusion:

Spiral woven mesh presents itself as a powerhouse material, offering strength, versatility, and a host of advantages. Its interlocking spiral design, coupled with its resistance to corrosion, heat, and pressure, positions it as an ideal choice for filtration, architecture, and industrial applications. With spiral woven mesh, industries gain a reliable and customizable solution for their diverse needs.

The Ultimate Guide To Woven Wire Mesh Filters

What are the three types of pipe fittings?

Who manufactures drill pipe?

Which Emerging Carbon Alternative will Replace Coal Carburizer?

Revolutionize Precastr Concrete Formwork with 2100Kg Shuttering Magnets: Boost Efficiency & Safety!

What are the advantages of purchasing nickel alloy 601 pipe and tubing?

Is perforated metal expensive?

Related Articles

Comments