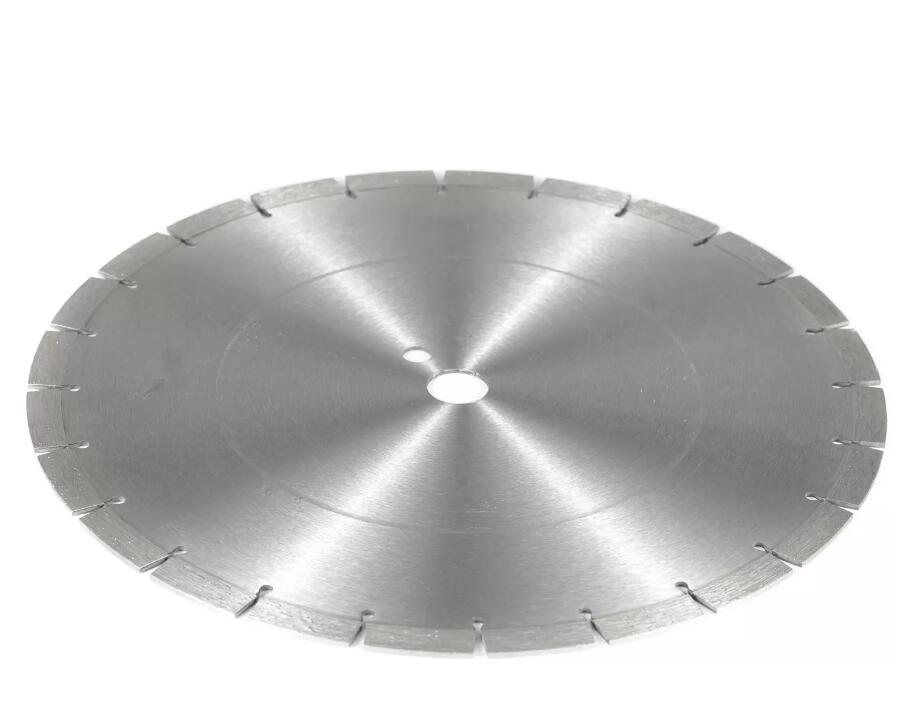

The Production Process of High-Quality Diamond Saw Blades

Diamond saw blades are tools commonly used in industrial processing to facilitate various cutting tasks. Today, we'll introduce the process for producing high-quality diamond saw blades.

Use of Stable Performance, Coarse-grain, and Thermally Stable Diamonds: Diamond tools are primarily composed of diamonds and a matrix fixed on a working substrate under specific manufacturing conditions. The quality, grain size, and concentration of the raw material, diamonds, play a crucial role in diamond tool production.

Incorporation of Strong Carbon Powder Elements: In the manufacturing process of diamond saw blades, if the blade's matrix has a strong hold on the diamonds, the diamonds will perform well, maintaining a sharp edge, preventing premature detachment, and ensuring high cutting efficiency. This can be achieved by coating the diamond surface with a layer of strong carbon compounds, such as titanium, chromium, nickel, tungsten, to enhance the bonding between the diamond and the matrix powder. Alternatively, small amounts of strong carbon powder elements like molybdenum, chromium, and tungsten can be added to the matrix powder. These powders have good wetting properties with diamonds, forming carbide alloys on the diamond and matrix metal surfaces during sintering, greatly improving the diamond's adhesion to the matrix.

Optimizing Diamond Grain Size Ratios: Traditional ratios often involve using coarse diamonds for sharper edges and fine diamonds for other applications. However, this approach doesn't always yield the best efficiency. Diamonds are highly hard and have a high elastic modulus, making plastic deformation difficult during high-temperature sintering. By selecting the right ratios and improving the packing density of diamond particles before sintering, better wear resistance for the blade can be achieved.

Utilizing Ultrafine Powders and Pre-alloyed Powders: Ultrafine powders lower sintering temperatures and enhance matrix hardness. Pre-alloyed powders, through three-dimensional mixing, reduce the contact time between the powder and air, preventing early loss and segregation of low-melting-point metals. This enhances sintered product strength and diamond retention.

Incorporating Rare Earth Elements: Adding trace amounts of rare earth elements like lanthanum and cerium to the matrix powder significantly reduces binder wear and enhances cutting efficiency.

Cold Pressing and Hot Sintering with Vacuum Protection Atmosphere: Quality Diamond saw blades are often cold-pressed and then sintered in a vacuum-protected atmosphere. This process results in exceptionally sharp blades with increased production efficiency. Vacuum protection prevents powder oxidation, activates sintering, improves blade performance, prolongs the life of graphite molds, and reduces production costs.

Correct Welding Techniques: For modern diamond circular saw blades, high-frequency welding is commonly used. During welding, improper techniques can lead to secondary "burning" of the blade and blade segment detachment. To ensure safety and productivity, high-strength, highly penetrative silver solder should be used for welding.

In summary, producing high-quality diamond saw blades involves using stable and thermally stable diamonds, optimizing diamond grain size ratios, incorporating strong carbon powder elements, utilizing ultrafine and pre-alloyed powders, adding rare earth elements, employing cold pressing and hot sintering in a vacuum-protected atmosphere, and using correct welding techniques. These steps result in blades that are sharp, efficient, durable, and cost-effective for various industrial cutting applications.

Comments