Advantages and application areas of Collapse Core Molds

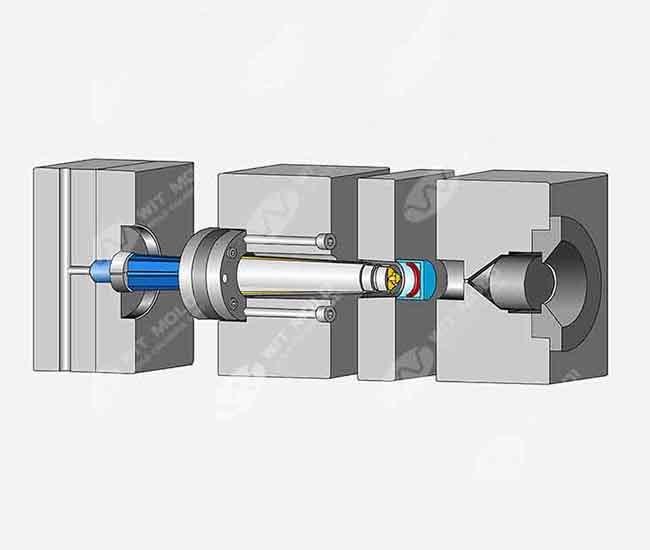

Collapse core molds, a sophisticated tool used in injection molding processes, offer numerous advantages and find versatile applications across various industries. Understanding their benefits and applications is crucial for optimizing manufacturing processes and enhancing product quality.

Advantages of Collapse Core Molds:

Complex Geometries: Collapse core molds enable the creation of intricate and complex part geometries with ease. The flexibility of these molds allows for the production of components with internal undercuts and intricate shapes that are challenging to achieve using conventional molds.

Reduced Tooling Costs: By eliminating the need for multiple slides and side-actions, collapse core molds can significantly reduce tooling costs. Manufacturers can achieve complex part geometries with a single mold, saving both time and resources in the production process.

Enhanced Part Quality: Collapse core molds ensure precise and consistent molding results, leading to enhanced part quality. The molds minimize the risk of defects such as sink marks, warpage, and flash, resulting in finished parts with excellent surface finish and dimensional accuracy.

Improved Cycle Times: With optimized design and efficient operation, collapse core molds contribute to shorter cycle times. The elimination of complex mechanisms and movements streamlines the molding process, allowing for faster production rates and increased throughput.

Versatility in Materials: Collapse core molds are compatible with a wide range of thermoplastic materials, including engineering resins and high-performance polymers. This versatility enables manufacturers to produce parts for various applications across industries such as automotive, aerospace, consumer goods, and medical devices.

Application Areas of Collapse Core Molds:

Automotive Industry: Collapse core molds are extensively used in the automotive sector for producing complex components such as interior trim panels, dashboard components, and exterior body parts. The molds enable the creation of intricate designs and integrated features that enhance vehicle aesthetics and functionality.

Consumer Electronics: In the consumer electronics industry, collapse core molds are employed for manufacturing casings, housings, and enclosures for electronic devices. The molds facilitate the production of slim and lightweight parts with precise detailing, meeting the demand for sleek and ergonomic designs.

Medical Devices: Collapse core molds play a vital role in the production of medical devices and equipment, including surgical instruments, diagnostic devices, and implantable components. The molds allow for the fabrication of intricate parts with complex geometries, ensuring compatibility with stringent medical standards and regulations.

Aerospace and Defense: In the aerospace and defense sectors, collapse core molds are utilized for manufacturing structural components, aircraft interiors, and military equipment. The molds enable the production of lightweight and durable parts with intricate features, contributing to the overall performance and safety of aerospace and defense systems.

Collapse core molds offer significant advantages in terms of design flexibility, cost-effectiveness, and manufacturing efficiency. Their versatility and ability to produce complex parts make them indispensable tools across a wide range of industries. Understanding the benefits and applications of collapse core molds is essential for manufacturers seeking to optimize their production processes and achieve high-quality results.

Comments