Honeycomb Extruded Porous Ceramic Filter: Paving the Way for Cleaner Industrial Processes

In various industrial applications, the need to separate solids from liquids or gases is a common challenge. Traditional filtration methods can be effective but often come with limitations, including clogging, maintenance, and reduced efficiency. This is where the Honeycomb Extruded Porous Ceramic Filter steps in as a game-changer. This innovative filtration technology has gained popularity in diverse industries, offering superior filtration, longevity, and cost-effectiveness.

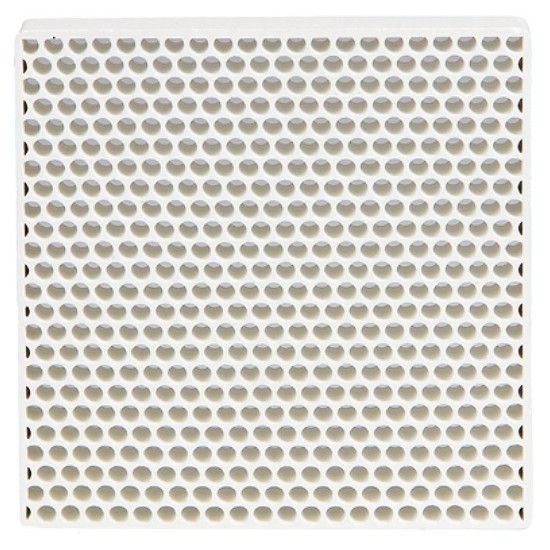

Understanding the Honeycomb Structure:

The Honeycomb Extruded Porous Ceramic Filter derives its name from its unique honeycomb structure. Composed of a network of interconnected channels, these filters are typically made from advanced ceramics. The channels, or cells, provide a high surface area for filtration while allowing for the unhindered flow of fluids or gases.

Advantages of Honeycomb Extruded Porous Ceramic Filters:

Exceptional Filtration Efficiency: Honeycomb ceramic filters offer precise filtration with the capability to capture particles as small as a few micrometers. This high level of filtration efficiency ensures that the end product meets quality standards.

Resistance to High Temperatures: These filters are engineered to withstand high-temperature environments, making them ideal for applications such as metal casting, foundries, and petrochemical processes.

Longevity: Due to their durable ceramic construction, Honeycomb Extruded Porous Ceramic Filters have a longer lifespan compared to conventional filters. This reduces the frequency of replacements, saving both time and money.

Low Maintenance: The non-clogging design of these filters minimizes maintenance requirements, ensuring a continuous and reliable filtration process.

Enhanced Fluid Flow: The honeycomb structure enables a higher flow rate while maintaining effective filtration, resulting in improved process efficiency.

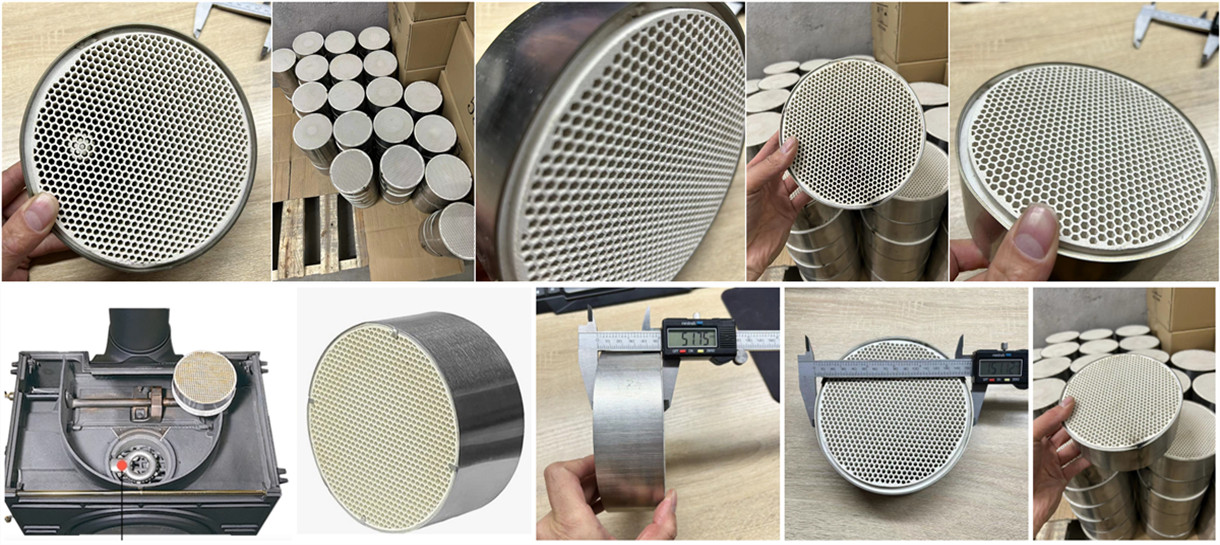

Applications of Honeycomb Extruded Porous Ceramic Filters:

Metal Casting: In the foundry industry, these filters are used to remove impurities and ensure a high-quality final product.

Welding: Honeycomb ceramic filters are employed in welding applications to eliminate welding fumes and maintain a clean working environment.

Oil and Gas: They find use in the oil and gas sector for filtering gases and fluids in high-temperature and high-pressure conditions.

Environmental Control: Industries dealing with air pollution control and emission reduction use these filters to clean and purify exhaust gases.

Automotive: In the automotive sector, these filters are utilized in catalytic converters for emissions control and particulate removal.

Chemical Processing: Processes involving chemical filtration and separation benefit from the precision and durability of honeycomb ceramic filters.

Honeycomb Extruded Porous Ceramic Filters have revolutionized the field of filtration with their exceptional efficiency, longevity, and adaptability to high-temperature environments. As industries continue to prioritize cleaner and more efficient processes, the role of these innovative filters becomes increasingly significant. Whether it's metal casting, environmental control, or automotive applications, the honeycomb filter's capacity to deliver reliable and consistent results makes it a top choice for modern industrial processes.

Comments