Revolutionizing Food Packaging with IML Technology

Revolutionizing Food Packaging with IML Technology.

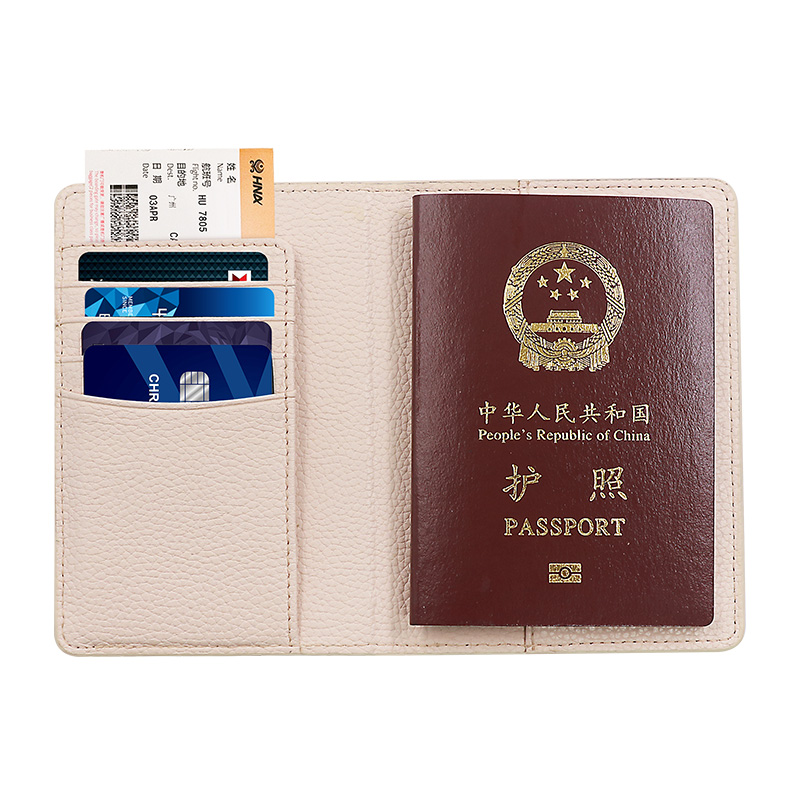

The advent of IML technology has transformed food packaging by seamlessly integrating labels into the packaging itself. Instead of the traditional method of applying labels separately after the packaging is manufactured, IML technology allows for labels to be molded directly into the packaging during the production process. This innovative approach not only enhances the visual appeal of the packaging but also provides greater durability, reducing the risk of labels peeling off or becoming detached over time.

The integration of labels also brings about significant efficiency improvements. With IML technology, the labeling process can be streamlined, eliminating the need for additional labeling equipment and reducing the time and effort required for labeling. This allows manufacturers to optimize their production processes, resulting in increased productivity and cost savings.

What are the advantage of a round glass bottle design?

Ultimate Guide to Customizing Household Product Labels: Boost Aesthetics & Safety

What is the use of seamless cylinder?

What are the advantages of using eco-friendly packaging film in your purchase process?

What type of rope holds up best in weather?

The Ultimate Guide to Opaque BOPP Film

Which advanced techniques optimize cell culture filter efficiency?

In addition to its efficiency benefits, IML technology offers enhanced design flexibility. Manufacturers can now create packaging with intricate and visually appealing designs that were previously challenging to achieve using traditional labeling methods. The use of IML technology enables the incorporation of vibrant colors, high-resolution images, and complex patterns directly into the packaging, elevating the overall aesthetic appeal of the product.

Moreover, IML technology has a positive impact on the environment. By eliminating the need for separate labels and reducing packaging waste, it contributes to the overall sustainability of the food packaging industry. Additionally, the integration of labels into the packaging enhances its recyclability, as there is no need for label removal before recycling. This not only reduces the environmental footprint but also aligns with the growing consumer demand for eco-friendly packaging solutions.

For more Ice Cream Tubs Wholesale, IML packaging factory, IML packaging for foodinformation, please contact us. We will provide professional answers.

Additional resources:What paper type do I choose for sublimation paper?

What are the top flexible packaging companies in the US?

What is LSR molding?

What are the advantages of a retortable pouch?

Beat the Summer Heat: Discover the Scoop on Super-Sized Ice Cream Containers!

Which pharmaceutical glass vial offers the best value for money?

What does 2 on bottom of glass mean?

Related Articles

Comments