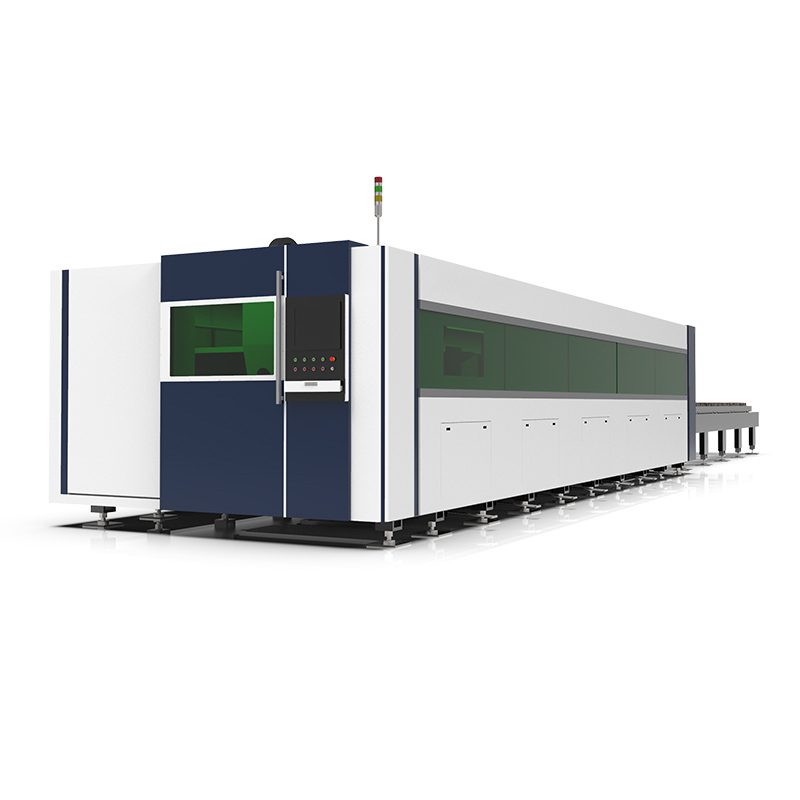

What are the daily maintenance of fiber laser cutting machines?

Fiber laser cutting machines use invisible beams to replace traditional mechanical knives. They have the characteristics of high precision, fast cutting, not limited to cutting pattern restrictions, automatic typesetting to save materials, smooth cuts, and low processing costs. They will be gradually improved or replaced. Based on traditional metal cutting process equipment. So what is the daily maintenance of fiber laser cutting machines?

Daily inspection of Fiber Laser Cutting Machines

1. Before starting the machine, check the pressure of the laser working gas and cutting gas. If the pressure is not enough, it needs to be replaced in time;

2. Check whether the X-axis, Y-axis, Z-axis zero point, laser ready status and other buttons are damaged (check the indicator lights).

3. Check the circulating water level in the chiller. If the water level is insufficient, add it in time;

4. Check whether there is any leakage in the circulating water channel of the external optical path. If there is any leakage, clean it up in time, otherwise it will affect the life of the optical lens;

5. After the daily work is completed, the waste materials at the work site should be cleaned up in time to keep the site tidy. The drain valve of the air reservoir at the bottom of the air compressor should be opened for drainage. After the waste water is drained, the water valve should be closed and closed in sequence according to the sequence of turning on and off the machine. Turn off the main power supply of the machine tool.

Regular maintenance of Fiber Laser Cutting Machines

1. Regularly clean the debris at the air exhaust outlet to ensure the ventilation effect;

2. Regularly check the filter in the gas line and remove accumulated water and debris in the filter in a timely manner;

3. Regularly check whether the travel switch bracket and impact block bracket screws are loose;

4. Clean the dust on the ventilation fan filter of the electric control cabinet in time to ensure good ventilation to facilitate heat dissipation of internal electrical components;

5. The X-axis guide rail and screw, Y-axis guide and screw, Z-axis guide and screw lubricant must be checked every other week to maintain the lubrication of all moving parts and extend the X, Y, Z-axis guide rails and screws. The service life of the bar;

6. Depending on the workshop environment, check the surface contamination of the reflector and focusing mirror from time to time (at least once a month), and clean the optical lenses in a timely manner to ensure their service life.

Additional resources:Universal Spline Hobbing Machine: Shaping Precision Gears

Understanding the Operation of a Pneumatic Chemical Injection Pump

What Drillers Should Know about PDC Bits

Powering Progress: Advantages and Applications of Slip Ring Induction Motors

Understanding the Chill: Exploring the Difference Between AC and Chiller Systems

Prolonging Pump Life: When and How to Replace Slurry Pump Parts

Pipe Rotators That Will Make Your Life Easier

Maintain optical lenses

1. Do not touch the surface of optical lenses (reflectors, focusing mirrors, etc.) directly with your hands to avoid scratches on the mirror surface. If there is oil stains or dust on the mirror surface, the lens should be cleaned in time;

2. Do not place the lens in a dark and humid place, as this will cause the lens surface to age.

3. If the surface of the lens is stained with dust, dirt, or water vapor, it is easy to absorb laser light and cause damage to the lens coating; at least it will affect the quality of the laser beam, and at worst, no laser beam will be produced.

4. When the lens is damaged, you should contact the Kingweike after-sales service department for repair in time. Try not to use the damaged lens, otherwise it will accelerate the damage to the lens that can be repaired.

5. When installing or replacing the reflector or focusing mirror, do not use too much pressure, otherwise it will cause the lens to deform, thus affecting the quality of the beam.

Daily maintenance of laser

1. Before turning on the laser, perform routine maintenance on the laser to ensure stable laser performance;

2. Check the cooling water pressure to ensure that the cooling water pressure is stable;

3. Check the cooling water temperature to ensure that the water temperature is within the suitable range of the laser;

4. Check the oil level in the laser vacuum pump. If it is not enough, add more;

5. Check whether there are any leaks in the oil, water, and gas lines of the laser.

Remember that while daily maintenance is essential, you should also schedule periodic maintenance by professionals to keep the machine in optimal condition. Regular and proper maintenance will help prolong the lifespan of your fiber laser cutter and ensure consistent, high-quality cutting results.

Harnessing the Power of Cleanliness: The 55W UV Sterilizer

Unleashing the Underground: A Comprehensive Guide to DTH Hammers

How Vertical Pressure Steam Sterilizers Keep Healthcare Safe

Choosing the Perfect MMA Welding Machine

Why Your Warehouse Needs a Rotary Arm Pallet Wrapping Machine

Microbulk Tank: The Ultimate Guide to Cost-Efficient Gas Storage

Demystifying the Cone Crusher Machine: Your Guide to Understanding its Function and Benefits

Comments