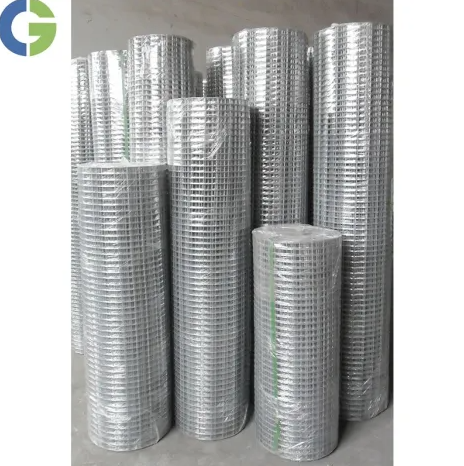

What is galvanized welded wire mesh?

Galvanized welded wire mesh stands as a stalwart in the realm of fencing, construction, and industrial applications, owing to its robust structure and corrosion-resistant properties. Let's embark on a journey to unravel the intricacies of galvanized welded wire mesh, exploring its composition, manufacturing process, applications, and the benefits it brings to diverse sectors.

1. Composition and Manufacturing:

Base Material: Galvanized welded wire mesh is crafted from high-quality steel wire. The wire's strength and durability contribute to the overall robustness of the mesh.

Galvanization Process: The steel wire undergoes a galvanization process to fortify it against corrosion. This process involves coating the wire with a layer of zinc, forming a protective barrier that shields the mesh from rust and corrosion.

Welding Technique: The wires are welded together at intersecting points, forming a grid-like pattern. This welding process ensures the structural integrity of the mesh, making it capable of withstanding various environmental conditions.

2. Applications:

Fencing Solutions: Galvanized welded wire mesh is a popular choice for fencing applications. Its durability and resistance to rust make it ideal for creating sturdy and long-lasting fences for residential, commercial, and agricultural purposes.

Construction: In the construction industry, galvanized welded wire mesh finds application in reinforcing concrete structures. It adds strength to concrete elements, such as slabs and walls, enhancing their load-bearing capacity.

Industrial Uses: Industries leverage galvanized welded wire mesh for diverse purposes, including creating enclosures, barriers, and partitions. Its versatility makes it suitable for applications in manufacturing facilities, warehouses, and industrial complexes.

Additional resources:

What is equivalent to uns N08825?

What are the top 5 benefits of using metal mesh screens for industrial purchases?

Everything You Need to Know About Flanged Ductile Iron Pipe

What is Calcium Carbonate? Benefits, Uses, and Side Effects Explained

What is metal palisade fencing?

Which magnesium is the cheapest?

Why Invar Alloy 36 is the Ultimate Solution for Thermal Expansion? Find Out Now!

3. Advantages:

Corrosion Resistance: The zinc coating acts as a powerful shield against corrosion, ensuring the mesh's longevity even in challenging environmental conditions.

Sturdy and Durable: The welding of wires creates a robust and stable structure, imparting strength to the mesh. This makes it capable of withstanding external forces and impacts.

Versatility: Galvanized welded wire mesh is available in various mesh sizes and wire gauges, providing versatility to cater to different requirements across industries.

Cost-Effective: Its durability and low maintenance requirements contribute to the cost-effectiveness of galvanized welded wire mesh over the long term.

Galvanized welded wire mesh emerges as a steadfast solution, seamlessly blending strength and corrosion resistance. From fortifying fences to reinforcing concrete, its applications span a wide spectrum. Whether employed for security, construction, or industrial purposes, galvanized welded wire mesh stands as a testament to the enduring strength derived from the marriage of steel and zinc.

What temperature is a refractory material resistant to?

The Top Benefits of Duplex Stainless Steels

Revolutionizing Aquarium Maintenance: Filter Foams Reimagined?

Choosing the Best Stainless Screen Mesh Size for Purchase: Tips on How to Make the Right Decision?

Color Steel Coil for Sale: Everything You Need to Know

Discover How Custom Steel Frames Can Revolutionize Your Build

Why Pre-fabricated Concrete Box is Revolutionary?

Related Articles

Comments