Which Automatic EPS Machine is Revolutionizing Packaging?

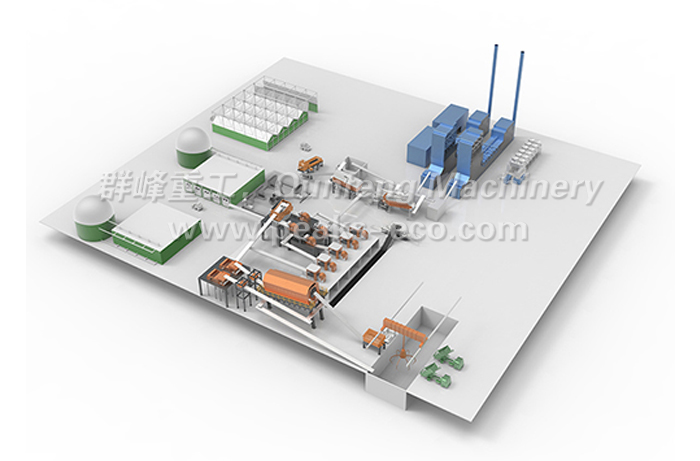

Packaging plays a pivotal role in ensuring product safety, quality, and presentation. Over the years, technological advancements have revolutionized the packaging industry, making processes more efficient, cost-effective, and environmentally friendly. One such groundbreaking innovation is the Automatic EPS (Expanded Polystyrene) machine. In this blog, we delve into the details of this remarkable machinery and explore its impact on the packaging industry.

Cutting-edge Technology and High Expertise:

The Automatic EPS machine represents the pinnacle of advanced technology in the packaging sector. From its inception, this machine has been built with precision and meticulous attention to detail. Equipped with intelligence, it streamlines the process of packaging, reducing human errors, and enhancing productivity levels. Its highly automated features ensure a faster turnaround time, making it an ideal solution for businesses that require efficient and reliable packaging processes.

Authoritative and Trustworthy Solution:

The Automatic EPS machine has gained a strong reputation in the packaging industry due to its track record of exceptional performance. Spanning numerous applications, it caters to a wide array of packaging requirements. Manufacturing companies across various sectors such as electronics, consumer goods, and pharmaceuticals rely on its accuracy and consistent results. In terms of its safety features, the machine is designed with fail-safe mechanisms, minimizing risks and ensuring secure operations.

Revolutionizing Packaging:

What truly sets the Automatic EPS machine apart from conventional packaging methods is its ability to adapt to diverse product shapes and sizes. With its innovative design, the machine is capable of customizing packaging solutions on demand, providing a seamless fit that envelops the products snugly. This adaptability makes it an ideal choice for fragile items and intricate components that require maximum protection during transit or storage.

With manual packaging, the process can be time-consuming and labor-intensive. The Automatic EPS machine takes efficiency to new heights by automating various stages of packaging, such as filling, sealing, and labeling. This not only minimizes the risk of human errors but also significantly reduces packaging time, enabling companies to meet even the most demanding deadlines.

Environmentally-friendly and Cost-effective:

Additional resources:Revolutionize Your Electronics Assembly with a Desktop Soldering Robot: Your Ultimate DIY Companion!

Which Produce Labeling Machine Best Saves Resources?

What are the advantages of buying a 3000psi Annular BOP in the purchase stage?

Which square tube laser cutting machine with CE certification is the best choice for efficient B2B purchase?

How does a multi head weigher calculate combinations?

Unlocking Performance: Mastering Honda Engine Valves

What are the advantages of using sucker rods in the purchase stage?

In an era where sustainability is a top priority, the Automatic EPS machine leaves a smaller carbon footprint than traditional packaging methods. By utilizing expanded polystyrene, a highly recyclable material, companies contribute to minimizing plastic waste and environmental degradation. Additionally, the machine's optimized utilization of resources reduces material costs, resulting in substantial savings for businesses in the long run.

Degree of Creativity and Burstiness:

Beyond its mechanical prowess, the Automatic EPS machine presents exciting opportunities for businesses to showcase their creativity. Brands can experiment with various packaging designs, textures, and colors, providing a visually appealing experience for consumers. In an increasingly competitive market, the machine's versatility allows companies to differentiate themselves by delivering unique and eye-catching packaging that captivates the target audience.

The machine's burstiness is evident in its adaptability to sudden shifts in packaging requirements. Whether there is a surge in demand or an urgent need for product rebranding, the Automatic EPS machine rises to the occasion, delivering results promptly and efficiently. Its ability to rapidly adjust to changing circumstances helps businesses remain agile in a dynamic market landscape.

A Human-like Touch:

While the Automatic EPS machine excels at automating packaging processes, it does not completely eliminate the human element. Skilled operators play an integral role in overseeing the system's operations, ensuring smooth functioning, and maintaining quality control. Furthermore, the machine's intuitive interface allows operators to program and monitor packaging specifications, granting them control and creativity in the production line.

Conclusion:

The Automatic EPS machine truly represents a groundbreaking innovation in the packaging industry. With its advanced technology, credibility, adaptability, and sustainable features, it has revolutionized packaging processes and raised the industry standard. By incorporating this cutting-edge machinery into their operations, businesses can enjoy increased efficiency, reduced costs, and unparalleled product protection. As packaging continues to evolve, the Automatic EPS machine stands as a testament to the power of innovation in shaping the future of packaging.

If you are looking for more details, kindly visit air bubble film making machine, Automatic EPS Foam Block Cutting Machine, 8l bottle blow molding machine.

Additional resources:Revolutionizing Warehouses with the Automated Pallet Flipper

The Future of Manufacturing: Can Cold Feed Rubber Extruder Machines Revolutionize Efficiency?

Which Tank Mounted Air Compressor is the Best for Long-Term Cost Efficiency?

Which is better cold-pressed or expeller-pressed avocado oil?

What is the process of marine boiler?

Which Automated Blow Molding Machine offers the best price-performance ratio in the market?

Boost Efficiency & Precision: Unraveling the Secrets of Spline Hobbing Machines

Related Articles

Comments