Which post press equipment is the best investment for boosting productivity and cutting costs?

Which Post Press Equipment is the Best Investment for Boosting Productivity and Cutting Costs?

In today's highly competitive printing industry, businesses are constantly seeking ways to boost productivity and cut costs. One area that often offers substantial opportunities for improvement is the post press stage of printing. This includes all the processes that take place after the ink is applied to the paper, such as binding, folding, cutting, and finishing. Choosing the right post press equipment can make a significant difference in both productivity and costs. In this article, we will explore some of the top post press equipment options available and discuss the benefits they offer.

Digital Finishers: Embracing Automation for Efficiency and Precision.

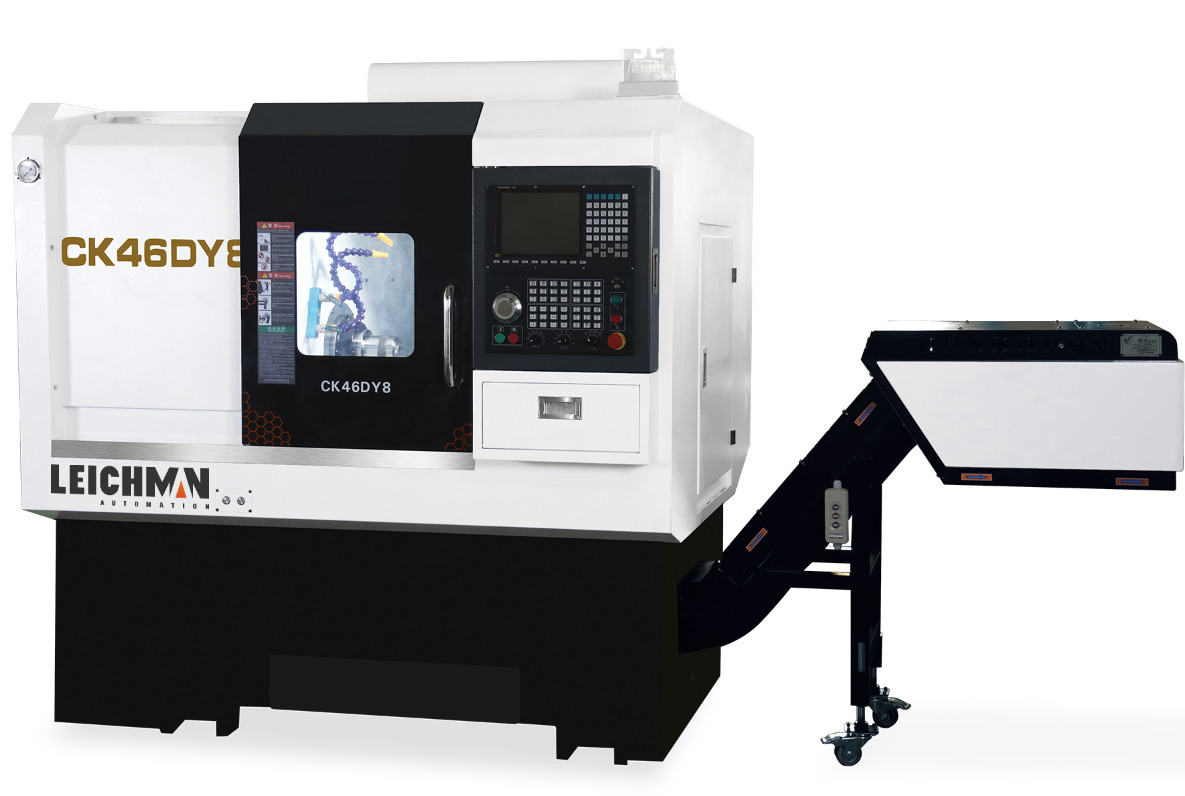

One post press equipment category that has seen notable advancements in recent years is digital finishers. These machines utilize advanced automation technology to streamline processes and achieve high levels of precision. Digital finishers can perform a variety of tasks, including cutting, creasing, folding, and binding, all in one machine. By eliminating the need for multiple machines and manual labor, digital finishers can significantly boost productivity while reducing costs. They also offer a high degree of flexibility, making it easy to switch between different types of jobs and formats.

UV Coating Systems: Enhancing Appearance While Reducing Drying Time.

UV coating systems have become increasingly popular in the post press stage due to their ability to enhance the appearance of printed materials. UV coatings provide a glossy and protective layer, giving a professional and finished look to the final product. Furthermore, UV coating systems offer the benefit of instant drying. Instead of waiting for conventional coatings to dry, which can take hours or even days, UV coatings dry instantly upon exposure to ultraviolet light. This reduces production time and allows for faster turnaround. Investing in a UV coating system can lead to improved productivity and reduced costs associated with drying time and waste.

Additional resources:What is the maximum load for a pallet truck?

Revolutionize Your Coating Process with ltcoatingline.com: How?

What device is used to detect radiation?

What is the best drill bit for a concrete lintel?

How Does Air Source Heat Pump Heating Work?

Everything You Need to Know About Chocolate Coating Machines: Tips, Tricks, and FAQs Answered

Is a dehydrator worth it for dog treats?

Automated Perfect Binders: Streamlining Binding Processes.

Perfect binders have long been a staple in the printing industry for producing high-quality books, magazines, and catalogs. Recently, many advancements have been made in the form of automated perfect binders. These machines can handle a wide range of book thicknesses and formats, all with minimal manual intervention. With automated perfect binders, the binding process becomes highly streamlined, resulting in faster production times and increased productivity. In addition, utilizing automated perfect binders can lead to cost savings by reducing labor requirements and minimizing errors.

Multi-function Cutters: Versatile and Efficient Cutting Solutions.

Cutting is a critical step in the post press stage, and having a versatile and efficient cutting solution can greatly impact productivity. Multi-function cutters offer a wide range of capabilities, including straight cutting, die-cutting, creasing, and even laser cutting. These machines can handle various materials, such as paper, cardboard, and plastics, making them highly versatile. By investing in a multi-function cutter, businesses can achieve greater precision, faster cutting speeds, and ultimately reduce costs associated with waste and rework.

In conclusion, investing in the right post press equipment is crucial for boosting productivity and cutting costs in the printing industry. Digital finishers, UV coating systems, automated perfect binders, and multi-function cutters are all excellent options that offer substantial benefits. By embracing automation, enhancing appearance, streamlining binding processes, and utilizing versatile cutting solutions, businesses can achieve higher efficiency, reduce labor requirements, and minimize errors. So, if you are looking to improve your post press operations, consider investing in the right equipment to enhance productivity and reduce costs.

To explore the best post press equipment for your specific needs, please do not hesitate to contact us. Our team of experts is ready to assist you in finding the optimal solutions for boosting productivity and cutting costs.

If you want to learn more, please visit our website Carton Inspection Machine, Gravure Printing Machine, Hot Foil Stamping Machine For Sale.

Additional resources:Revolutionizing Snack Industry: Granola Bar Extruder?

Revolutionizing Pet Care: The Dog Bone Machine?

Ultimate Guide to Pet Biscuit Trays: answers to all your questions

Enhancing Safety and Quality Control: The Importance of Glove Leak Detection Machines

What are the benefits of using a hydraulic mill roll stand?

Choosing the Right Bottle Bagging Machine for Your Packaging Needs

Vane Compressors: The Workhorses of Efficient Air Compression

Related Articles

Comments