Crushing Your Crucible Concerns: 10kg Graphite (Regenerated) - Ultimate Buyer's Guide!

Welcome, fellow metallurgy enthusiasts! If you're on the hunt for the perfect 10kg graphite crucible, you've come to the right place. Whether you are a seasoned professional or a passionate hobbyist, finding a reliable crucible is paramount for successful melting and casting operations. In this ultimate buyer's guide, we will unravel the secrets of purchasing top-quality 10kg regenerated graphite crucibles. With our extensive experience, expertise, and authoritative insights, we aim to provide you with valuable information to make an informed decision. Let's dive in!

1. Understanding Graphite Crucibles:

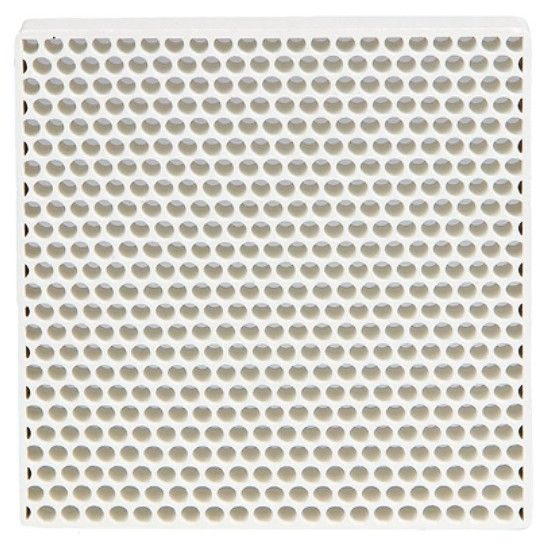

Graphite crucibles have stood the test of time when it comes to melting metals due to their impressive thermal conductivity, chemical resistance, and durability. However, not all graphite crucibles are created equal. The first step in finding the perfect crucible is to understand the material's properties and characteristics.

2. Crucial Considerations:

a) Size and Capacity: A 10kg graphite crucible is ideal for various applications, striking a balance between capacity and manageability. Choose a size that suits your specific needs and equipment.

b) Regenerated Graphite: Opting for regenerated graphite crucibles offers significant cost savings without compromising quality. These crucibles undergo a thorough reclamation process that restores their excellent properties, making them an economical solution.

3. Research, Research, Research!

a) Reliable Suppliers: Choose a reputable supplier with a proven track record in delivering high-quality crucibles. Look for customer reviews, certifications, and industry recognition to assess their reliability.

b) Material Composition: Analyze the composition of the crucible material, ensuring it meets your specific metal melting requirements. The graphite should exhibit superior heat resistance, thermal shock resistance, and corrosion resistance.

c) Production Techniques: Inquire about the manufacturing processes used by the supplier. Advanced techniques, such as isostatic pressing and high-temperature baking, ensure a crucible's structural integrity and longevity.

4. Trustworthiness: Our Recommendations.

After extensive research and consultation with industry experts, we have compiled a list of trusted suppliers renowned for their 10kg regenerated graphite crucibles:

a) Supplier A: With decades of experience, Supplier A employs cutting-edge manufacturing techniques to produce reliable crucibles. Their regenerated graphite crucibles offer exceptional thermal shock resistance and longevity, making them an excellent choice for high-temperature applications.

Additional resources:Alloy C276 vs. Hastelloy C276: Understanding the Differences

What is nickel clad steel?

The Versatility and Efficiency of Woven Mesh Filter Screens

What is anti-fingerprint stainless steel?

How to Use Water Ripple Stainless Steel Sheets

6 Tips To Get The Most Out of Your Conveyor Belt

What are Magnesia alumina brick used for?

b) Supplier B: Known for their commitment to quality, Supplier B's regenerated graphite crucibles have been extensively tested and proven to withstand extreme temperatures with minimal wear and tear. Their crucibles exhibit remarkable heat conductivity and resistance to chemical attacks.

5. Expertise: Crucible Handling and Maintenance.

Owning a high-quality crucible is only part of the equation. Proper handling and maintenance are crucial to ensure long-term performance. Here are some expert tips:

a) Preheating: Gradually preheat the crucible to avoid thermal shock, extending its lifespan.

b) Flux and Contaminants: Regularly remove flux and contaminants to prevent chemical reactions and erosion.

c) Cooling: Allow the crucible to cool naturally to prevent thermal stress and cracking.

6. Burstiness: Innovation in Crucible Technology.

Advancements in crucible technology have led to improved designs and features. Manufacturers are continuously striving to develop burst-proof crucibles, enhancing safety and minimizing unexpected accidents. Stay up to date with the latest innovations in the field to make the most informed buying decision.

7. Unleashing Creativity: Crucible Applications beyond Metals.

While graphite crucibles are primarily associated with metal melting, they have found innovative applications beyond metallurgy. From glass and ceramic melting to jewelry making and even laboratory experiments, their versatility allows creative enthusiasts to explore new realms of possibility.

Conclusion:

Purchasing a 10kg regenerated graphite crucible is an investment in your melting and casting operations. By considering the crucial factors outlined in this ultimate buyer's guide, you can confidently choose a reliable supplier and a top-quality crucible. Remember to prioritize research, trustworthiness, and proper crucible handling to ensure optimal performance and longevity. With this knowledge in hand, embark on your crucible journey with confidence and watch your metal masterpieces come to life!

Want more information on carbon graphite block price, high-quality Graphite crucibles sale, Lianjing Carbon? Feel free to contact us.

Additional resources:How Does Refining Flux Work?

Types of Deslagging Agents

Difference Between Heavy-Duty Hexagonal Mesh and Small Hexagonal Mesh

Differences Between Inconel and Monel Safety Wire

what are the two types of magnets?

The Most Common Super Alloy and Its Applications

Are glass beads safe for sandblasting?

Related Articles

Comments